We offer materials that support your thermal processing and thermo chemical process. Our composites are especially coated, sintered and hardened, which helps you to handle processes from 572°F until 5432°F.

Our fibre reinforced composites guarantee high load capacity with low net weight and high temperature solidity. The chemical constancy and features of our KOMPOSITe`s are adjusted to your particular process.

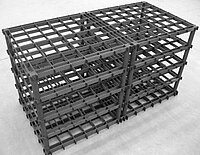

Carrying constructions are manufactured in different thicknesses and lengths and according to your requirements. Chargers, grids, baskets, separators and rails are made out of carbon fibre reinforced carbon, carbon-ceramic fibre reinforced ceramics. Plasma guiding tubes and exhausts are made out of individually manufactured reinforced ceramic matrix composites. Poles, columns or tubes can be manufactured from graphite or fibre reinforced carbon ceramic composites. We will be happy to advice you the best solution.

For temperatures until 5432°F (vacuum), we recommend our composites:

• KOMPOSIT-C,

• KOMPOSIT-C/C,

• KOMPOSIT-C/SiC,

• CFC-PAN,

• CFC-MC.

To prevent carbonization of processed parts, we recommend our sandwich system, which consists of two solid composites, created through material fusion, leading into one panel. For example: The carrier is made from KOMPOSIT-C (carbon fibre reinforced ceramics) and the cover plate from KOMPOSIT-A, which is reinforced Al2O3 fibre reinforced ceramic.

*More technical details on special request.

![[Translate to English:] [Translate to English:]](/fileadmin/_migrated/media/keyvisual22.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_migrated/media/keyvisual33.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_migrated/media/keyvisual_01.jpg)