Carbon fibre reinforced carbons have been developed in the early 60`s for manufacturing of lightweight materials with strong mechanical characters and have been applied in aeronautics, aerospace and spacecraft construction. Today CFRC are widely implemented in industrial processing.

CFRC have a carbon matrix with carbon fibre reinforcement and consist from more than 98 percent of pure carbon. Manufacturing of CFRC requires significant amount of energy investment and a relatively long term processing. Carbon fibres are usually laminated with organic resin systems, cured and vacuum processed at very high temperatures. The process of the pyrolysis lasts at least 2 months. Our CFRC, manufactured with this processing are named CFC-PAN and based on Polyacrilnitril fibres.

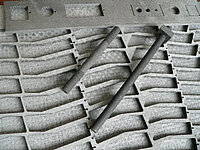

Another processing technology incorporates gas phase carbonization. Using this technology allows CFRCs to be manufactured in shorter period of time and have a very solid and tough surface and body. In this so named, Chemical Vapor Deposition, the carbon fibres build a solid system, with the reactive gas created matrix. Our CFRC`s built through CVD or CVI technology are named CFC-MC.

Our CFRC materials have outstanding mechanical characteristics. Their applications are: research & development, aeronautics, aerospace, special industries, glass manufacturing industry, furnace construction, process equipment, heat treatment, reimbursement, metallurgy, generating energy & power plants.

Our CFRC resist temperatures up to 4532°F in Vacuum. In order to improve oxidation resistance at normal atmosphere, we infiltrate our CFRC with anti oxidative ingredients.

For standard measurements and more information about our CFRC products please send your commercial enquiry.

![[Translate to English:] [Translate to English:]](/fileadmin/_migrated/media/keyvisual22.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_migrated/media/keyvisual33.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_migrated/media/keyvisual_01.jpg)